Industrial Solutions

Provide customers with the most appropriate waterjet process solution.

Industrial Solutions>Aerospace

| Solution | Process | Materials | Application |

|---|---|---|---|

| Cutting & machining | Cutting | Composites CFRP | Spacers, ribs, blades,.. |

| Roughing | Inconel, Titanium, Stainless, Aluminum,... | Blisks, Blades, Leading Edges... | |

| Drilling | Titanium, Inconel... | Plugs, Nacelle Parts... | |

| Degating | Inconel, Titanium, Aluminum | Lost-wax foundries | |

| Deflashing | Inconel, Titanium | Forges / Blades, Landing gear | |

| SurfaceStripping or BlastingAbradable Coatings...Vanes, Blades... | |||

| Thermal Barrier Coatings | Blades, Combustors... | ||

| Knock-Out | Ceramic Shells/Cores | Lost-Wax Foundries |

Features

- Over 10years experience in designing, building, running, developing, servicing…Waterjet Systems for the Aerospace industry

- Advanced manufacturing processes and custom solutions for precision parts.

- Provide customized software, system and service based on professional technologies and ultra-high pressure solution

Machining

Features

Ultrahigh-pressure abrasive waterjet (AWJ) cutting and machining is an excellent solution for processing advanced materials, including titanium, super alloys, and composites.

- Processing advanced materials like titanium, super alloy, composites

- No heat affection

- No geometry limitation.

- No pressure transmitted to the part

- Unique work with full 3D cutting

- Comprehensive and intuitive user interface

- Green environment with soundproof enclosure and effluent water treatment

Removal

WJS

Features

The water condensed at high pressure is jetted on the surface of the material to remove chemical substances and coatings.

- No deformation from heat, friction & corrosion

- Time saving up to 10 times faster than chemicals

- Single process to removes all coating types

- Eco friendly : releases no pollutant

| Stripping range | |

|---|---|

| Base material | Coat material |

| Inconel | Rubber |

| Titanium | Abradable & Polymers |

| Titanium Aluminide | Metal & Alloys |

| Stainless steel | Ceramics |

| Aluminum | Carbide |

| steel... | |

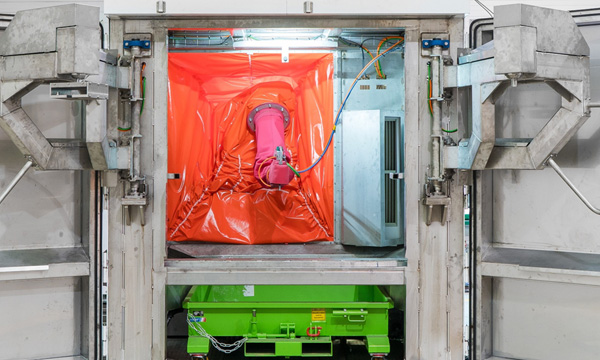

CSR

Features

High pressure waterjet blasting is the ideal solution for ceramic shell and core removal on any investment, lost wax, or plaster casting for any material.

- Preserve delicate parts with thin walls and/or sharp edges

- Knock out and core removal of any investment, lost wax, or plaster casting

- Ideal for complex 3D super alloy parts

- A single process removes both shell and core

- No chemicals or toxic waste

- Fast, repeatable process

| Blasting material |

|---|

| Aluminum |

| Steel |

| Titanium |

| Super alloys |

If you have any further reuqest or question on TOPS waterjet solution & service;

Contact Us